Office of the Secretary of Defense Designing and Procuring Greener Weapon Systems

Chemicals are essential components in Department of Defense (DoD) weapon systems, but DoD faces long-term risk from its use of hazardous and toxic chemicals and materials. Employment of these chemicals and materials can produce compliance and cleanup costs, generate health claims and increase lifecycle costs of weapon systems and facilities. The Department must protect people and readiness by reducing use of such high-risk contaminants and hazards, both known and emerging. New restrictive laws and regulatory standards have implications for DoD’s readiness, which include training and supply chain effects. For example, restrictions can affect the performance, cost and schedule of new weapon systems acquisition, as well as their maintenance and the availability of chemicals necessary for their operation. Therefore, the Department is moving toward a lifecycle approach for the selection, management, use and disposal of chemicals and materials in weapon systems and facilities.

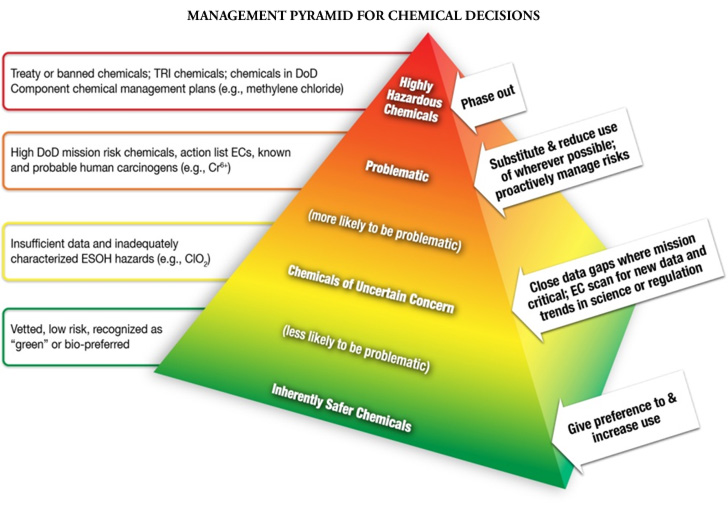

Figure 1 reflects the premise of this new chemical management strategy, as envisioned by the Office of the Deputy Under Secretary of Defense for Installations and Environment, ODUSD (I&E). The Defense Department has a number of policies and programs in place to reduce use of hazardous and toxic materials upon which this pyramid is based. This paper highlights different, but mutually supporting, aspects of DoD’s approaches to improving chemical management and to protecting, and even enhancing, mission capabilities.

Acquisition and Procurement

Making the decision to decrease the chemical footprint of new and existing (i.e., “legacy”) weapons systems is a powerful first step in ensuring continuing capabilities and cost savings. This is because the bulk of weapon system platform lifecycle costs (> 60 percent) are associated with its sustainment in the operation/support phase. For electronics, fully 95 percent of these costs can be locked-in by completion of the design phase. Furthermore, since many of DoD’s hundreds of legacy systems require upkeep for several years, if not decades, chemical and material choices must consider long-term material availability and future increases in handling and disposal costs.

As the single largest buyer of supplies and services in the Federal government, DoD should strive to ensure every procurement meets requirements of applicable green procurement preference programs. The Defense Department established its Green Procurement Program (GPP) to enhance and to sustain mission readiness through cost effective acquisition that achieves compliance and reduces both resource consumption and solid and hazardous waste generation. Green procurement includes acquisition of:

- Recycled content products;

- Environmentally preferable products and services;

- Biobased products, energy– and water-efficient products;

- Alternate fuel vehicles and alternative fuels;

- Products using renewable energy; and

- Alternatives to hazardous or toxic chemicals.

The GPP applies to all acquisitions from major systems programs to individual unit supply and service requisitions. In its day-to-day operations, DoD has the opportunity and obligation to be environmentally and energy conscious in its selection and use of products and services. Proper attention to green procurement enhances the Department’s commitment to environmental stewardship by becoming a model consumer of green products and services.

Among the GPP objectives are:

- Educating all appropriate DoD employees on the requirements of Federal “green” procurement preference programs, their roles and responsibilities relevant to this program and the DoD GPP, and the opportunities to purchase green products and services;

- Increasing purchases of green products and services consistent with mission demands, efficiency and cost-effectiveness, with continual improvement toward Federally established procurement goals; and

- Expanding markets for green products and services.

In addition to training on Green Procurement, DoD offers a new online training course, Chemical Ranking Systems for Strategic Material Selection, known as CLE 067 on the Defense Acquisition University’s website. Designed for acquisition professionals in program management, engineering and technology career fields, the course describes best practices for chemical management within Military Departments (MilDeps). The intent behind green procurement and chemical selection training is to raise awareness of costs and benefits associated with chemical selection, and to provide information and tools to improve choices and behavior.

Recent History of DoD’s Chemical Management

In the 1990s, DoD implemented the “Hazardous Material (HazMat) Pharmacy” concept to provide increased cradle-to-grave control of chemicals of concern (COCs) on DoD installations and to support Environment, Safety and Occupational Health (ESOH) program goals. The concept is based on single-point control, tracking and accountability over requisitioning, distributing, issuing and re-issuing hazardous materials. Beginning with the Air Force (AF), the HazMat pharmacy approach has since been adopted by the Army, and is known as the Consolidated HazMat Reutilization and Inventory Management Program, or CHRIMP, in the Navy. The pharmacy model applies a three-stage approach to control HazMat inventories from requisition to disposal:

- Acquisition and authorization;

- Distribution, dispensation and collection; and

- Tracking and accounting.

Some benefits of HazMat pharmacy to both mission and sustainability are:

- Increased awareness of less toxic or non-hazardous products and processes, which reduce use of hazardous materials and associated hazardous waste disposal costs;

- Improvements to worker health and safety; and

- Assurance of proper chemical storage (e.g., preventing co-location of incompatible materials).

After Naval Air Weapons Station at Point Mugu, California, implemented a HazMat Minimization Center as an integral part of its base-wide HazMat pharmacy, hazardous material purchases were reduced from $132,000 to $55,000 the first year of operation. In its second year, a further reduction of $43,000 was realized. The AF maximized effectiveness of its HazMat pharmacy programs by tying them into the AF Environmental Management Information System, or EMIS, an automated data processing program. The pharmacy at Andrews Air Force Base (AFB), Maryland, virtually eliminated redundancy in procurement of hazardous materials across multiple Services using the base. At Hill AFB, Utah, material acquisition costs decreased from $11 million to $3.6 million in just one year.

Photo by Staff Sgt. Corenthia Fennell

In 2006, DoD created its Emerging Contaminant (EC) Program to proactively identify and to manage risks associated with chemicals and materials the Department uses. It looks to research trends and scientific literature, and monitors activities of regulatory agencies to identify ECs. DoD determines which ECs it uses, or plans to use, and ascertains how they are used. By means of a subject matter expert elicitation process for a specific EC, the Department then assesses (1) potential impacts of the science, toxicity or regulatory changes on people and environment, and (2) potential impacts on DoD business functions and mission, considering both likelihood and severity. For those chemicals or materials posing high future risks, the program identifies and tracks proactive efforts to manage risks before new regulatory requirements are put in place. Risk management measures depend upon the chemical and its use, and can include site-specific risk assessment, development or testing of alternative chemicals or processes, and investment in new protective equipment or improved cleanup technologies.

As a result of the EC Program, the Department issued a policy memorandum in April 2009, Minimizing the Use of Hexavalent Chromium. Hexavalent chromium is often found in products used for corrosion protection, and is a known carcinogen. In May 2011, DoD also amended the Defense Federal Acquisition Regulation (DFAR) with regard to hexavalent chromium. The rule codifies DoD policy for addressing serious human health and environmental risks related to use of products containing hexavalent chromium, and prohibits the Department from acquiring items containing more than 0.1 percent of it by weight in new systems, unless no acceptable alternative to its specified use exists.

The program also identified that cap-and-trade schemes, or international restrictions, might affect DoD’s use of some greenhouse gases (GHG). The Emerging Contaminant Program looked at sulfur hexafluoride, a critical dielectric material, which is also an extremely potent GHG. This GHG remains in the atmosphere for up to 3,200 years, and has a global warming potential (GWP) 23,000 times higher than carbon dioxide throughout a 100-year period. In October 2010, DoD issued policy directing MilDeps to develop and to implement procedures to reduce, to capture and to recycle sulfur hexafluoride where it is operationally, technically and economically feasible. At the same time, the Department is researching ways to reduce sulfur hexafluoride leakage and is searching for alternatives to replace it. By looking ahead, the Emerging Contaminant program guarantees that small, upfront investments can ensure continued mission capabilities so DoD avoids costly, crisis retooling.

Plans Enhancing Chemical Management

Since 2008, the ODUSD(I&E) has instituted three plans to help design and procure greener weapons platforms, defense products and related processes. These include:

- Agency-Level Toxic and Hazardous Chemicals Reduction Plan, as mandated by Executive Order (EO) 13423, Strengthening Federal Environmental, Energy and Transportation Management;

- Managing Chemicals, Material, and Impacts to Readiness from REACH 1 : A Strategic Plan; and

- Strategic Sustainability Performance Plan (SSPP), as mandated by EO 13514, Federal Leadership in Environmental, Energy and Economic Performance.

While each of these plans has a different focus, there are some important commonalities. When taken together, these synergies help reduce DoD’s total ownership costs and proactively manage mission risks associated with chemical and material uses.

I. Agency-Level Toxic and Hazardous Chemicals Reduction Plan

Reducing use and release of hazardous and toxic chemicals and materials helps avoid operational disruptions resulting from environmental protection restrictions and permitting processes, and reduces handling and disposal costs. These chemical reductions and phase-outs minimize degradation of local air and water quality that potentially impairs the health of both military and civilian communities. Proper management of hazardous and toxic chemicals and materials also protects ecosystems and range lands needed for training, thus ensuring continued military access to those areas.

Promulgated in 2008, the plan describes DoD programs, initiatives and actions necessary to reduce procurement, use, release and disposal of toxic and hazardous chemicals, as mandated by EO 13423. Progress to date reported by the MilDeps includes application-specific reductions in:

- Ozone Depleting Substances (ODSs) ranging from 10-100 percent;

- Toxics Release Inventory (TRI) chemicals ranging from 10-80 percent; and

- Hexavalent chromium (a known carcinogen) and lead (a neurological toxicant) at 47 percent and 98 percent, respectively.

II. Managing Chemicals, Materials and Impacts to Readiness from REACH

© iStockphoto.com/ugurhan

Enacted in 2007, REACH effectively replaced 40 chemical-related laws in the European Union (EU) for some 27 Member States and at least three neighboring countries. The goals of REACH are the earlier and better identification of chemical exposure risks with an eye on promoting the competitive edge of the European chemical industry. REACH-like initiatives have begun to appear in other countries and within U.S. state and local governments. No blanket defense exemption exists under REACH, although individual European Ministries of Defence (MODs) can apply for narrow defense exemptions. These exemptions are predicated on lack of feasible, application-specific alternatives. U.S. companies, including DoD’s Original Equipment Manufacturers (OEMs) and defense suppliers wanting to do business in the EU, must use an EU representative to register their products prior to taking them to market. Just as EU’s Restriction of Hazardous Substances, or RoHS, impacted commercial-off-the-shelf products (COTS) in defense electronic supply chains with the switch to non-leaded circuitry, REACH is expected to do much the same, i.e., cause chemical re-formulations, only for far more COTS products.

The toxic and hazardous chemical reduction plans executed by MilDeps have helped to prepare DoD for some of the cost, performance and availability issues associated with adoption of REACH. But the Department needs to do more to ensure mission capabilities as REACH is implemented. In 2010, DoD issued its strategic plan for REACH to safeguard military readiness in the face of these potential changes since many defense products must work longer and harder than their commercial counterparts. Chief among the plan’s goals are:

- Protecting availability of substances in the supply chain that have no viable substitutes and whose elimination would cause an adverse impact on the defense mission;

- Ensuring adequate performance of substitutes adopted in mission-significant applications; and

- Guarding against disruptions to the supply chain, as a result of REACH.

Collectively, the strategic plan’s goals and associated objectives strive to:

- Identify strategies and solutions to promote potential positive, and to minimize potential negative, impacts of REACH;

- Provide a roadmap to unify, coordinate and communicate those activities across DoD; and

- Reduce use of toxic and hazardous chemicals wherever feasible.

The plan is available at: www.denix.osd.mil/cmrmd/ChemicalManagement/TSCA.cfm.

The REACH strategic plan also promotes the Department’s objectives under its Strategic Sustainability Performance Plan (SSPP) to minimize use and release of environmental COCs while reducing toxic and hazardous chemical exposure to its workforce.

III. Strategic Sustainability Performance Plan

DoD’s SSPP focuses the Department’s efforts on the national goal of reducing energy consumption while maintaining the mission to defend and to protect the nation. SSPP is far broader than energy efficiency and expansion of renewable energy sources; it also includes many aspects of chemical management from toxics reduction and electronics reuse and recycling to pesticide use and integrated pest management. A relationship exists between energy usage and chemicals for some products used by DoD and industry alike. For example, without an appreciation for lifecycle costs, replacement of some environmentally hazardous, solvent-based degreasers with aqueous, that is, water-based cleaners, may simply shift pollution risk from manufacturer site to power plant since many of these substitutes require heat application to function properly.

Of this plan’s eight goals, goal No. 6 requires minimization of use and release of COCs, and accompanying reductions in on-site and off-site transfers of toxic chemicals. Continued TRI reductions as reported under EO 13423 qualify for this category, as do many chemicals regulated under REACH.

Conclusion

Anticipating developments at international, national and state levels will inform chemical-usage decisions made by DoD today and promote military readiness for tomorrow. Enterprise-wide management of selection, acquisition, distribution, use and disposal of chemicals will better prepare DoD, and any other institution, for potential future regulatory initiatives.