CH2M HILL Better Environmental Remediation Outcomes

Tug on anything at all and you’ll find it connected to everything else in the universe,” said conservationist John Muir. Nowhere is this more accurate than in remediation – the science of cleaning-up contaminated sites. Addressing problems caused by poor past practices tugs on a lot of strings, such as greenhouse gases (GHG) generated by heavy equipment. From life-cycle impacts of materials, fuel, chemicals and energy used in site cleanups to impacts on natural areas and resources to environmental justice, it takes diligence to make sure benefits to site, community and environmental systems are optimized and negative impacts minimized. Integrating sustainable principles – thinking long-term about environmental, social and economic remediation impacts – avoids doing harm and could produce benefits in ways not previously imaginable.

Instead of focusing on just cleaning-up a site and simply getting rid of what is “bad,” artfully tugging on those strings can create abundant opportunities for doing good. This includes: productive reuse of waste materials, enhancement of ecosystem services (the benefits people derive from the environment and biodiversity) and even job creation.

The first step in incorporating sustainability is to abate significant risks to humans, wildlife and environment while minimizing impacts to the post-remediation landscape and optimizing its value for future use. For example, will excavating a wetland cause more harm than good? For a highly urbanized river, will sediment removal result in a net benefit given that the area will still experience general runoff and high flows? Would additional remediation allow for unrestricted use and generate significant economic opportunity? Could recreational areas be incorporated into a soil cover placed over a site?

The second step is to examine techniques used to conduct the remediation project itself. Technologies should be optimized to minimize environmental and cost burdens by applying low-impact materials and processes. Through optimization, remediation projects can be designed to produce future benefits for society and environment.

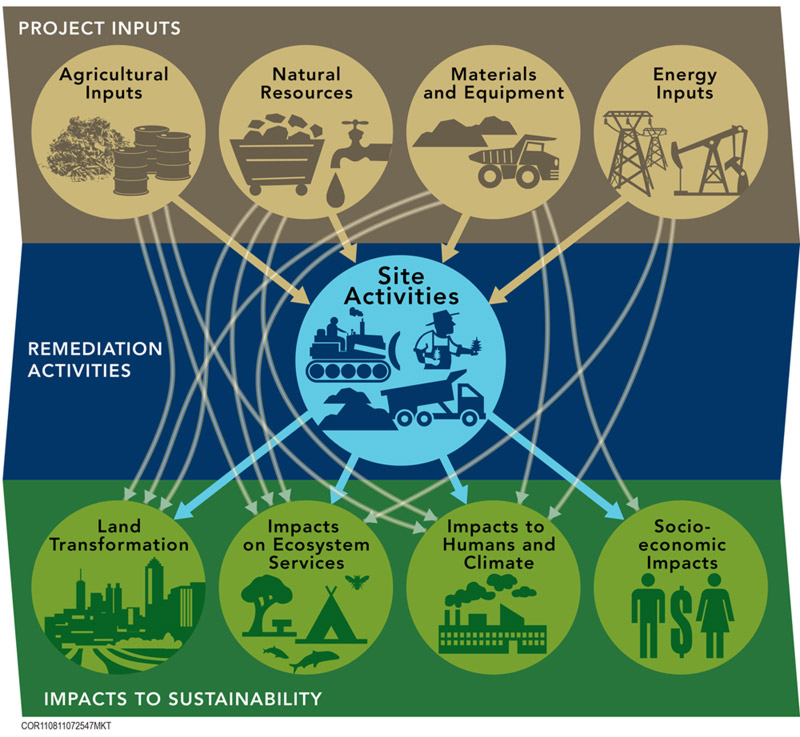

|Even the greenest remediation projects can have impacts on air, water, soil and land. Environmental, community and economic impacts can all occur from inputs used in remediating a site as well as from site activities themselves. Evaluating these creates opportunities to reduce or to mitigate impacts and to optimize design for sustainability.

Uncover Hidden Gems

Taking a life-cycle view of a remediation project gives engineers and scientists holistic insight into every chemical and resource that goes into a remediation project. It also helps to foster an understanding of environmental burdens generated by the life-cycle of remedial action. Life-Cycle Assessment (LCA) practice allows remediation professionals to tug on strings and to find connections among component processes, materials, energy and resources of a remediation project. LCA allows environmental impacts to be considered and estimated, such as fossil fuel depletion, agricultural impacts, land transformation, ozone depletion, photochemical oxidant formation, acidification, water depletion, human and surface water toxicity, and more.

By understanding burdens and where they come from, practitioners are better equipped to consider options for remediation. For example, if a green treatment reagent like emulsified vegetable oil is going to be used in large quantities, the material could be sourced from suppliers practicing sustainable agriculture to minimize environmental impacts. Likewise, if a large amount of sodium hydroxide will be used, material could be sourced from facilities using a greener energy rather than a mercury cell process.

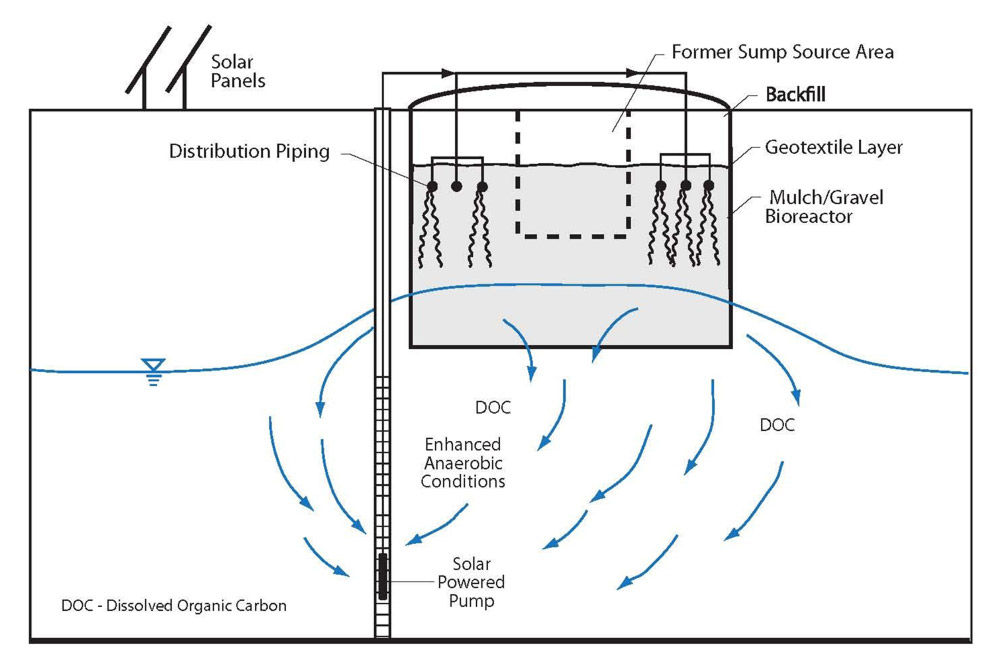

An example of long-term, sustainable thinking can be found at Travis Air Force Base (AFB), Calif., where solvent-contaminated groundwater required treatment and remediation. Before embarking on their optimization initiative, Travis AFB had four traditional pump-and-treat groundwater treatment systems using approximately 30,000 kilowatt hours (kWh) of electricity per month. By switching to a solar-powered bioreactor; replacing the high-energy, ultra-violet oxidation system with activated carbon; and implementing other efficiencies, they reduced electrical consumption by 78 percent. Combined with a reduction in furnace use, an 83 percent decrease in GHG production was achieved for all remediation systems.

According to Mark H. Smith, Travis AFB restorations manager: “Green Sustainable Remediation (GSR) uses common sense when looking at the entirety of a cleanup operation. GSR focuses on all factors that go into a cleanup, such as energy usage, material production and vehicle usage, which can affect the final decision of how a site cleanup should be carried out. Our two bioreactors are perfect examples of GSR utilization. We are accelerating cleanup of two challenging sites without using electricity from the grid. Considering the fiscal constraints all federal agencies face today, this strategy helps to meet remedial action requirements while conserving precious energy resources and reducing energy costs.”

Basically, contaminated groundwater is circulated by a pump powered by the sun through wood mulch. This process cleans groundwater by adding natural organics that help bacteria degrade contaminants. The bioreactor consists of a blend of tree mulch (produced onsite), vegetable oil and gravel placed as backfill in a small excavation. Contaminated groundwater from the site is extracted from the aquifer and re-circulated through the in-situ bioreactor. The bioreactor creates the anaerobic environment needed to degrade chlorinated solvents, eliminating the need for above ground treatment and extending the treatment into the soil/aquifer matrix.

|The water treatment bioreactor at Travis Air Force Base uses onsite mulches and the power of the sun to remove solvents from contaminated groundwater.

After two years of operation, the bioreactor has achieved a 95 percent reduction in total solvent concentrations. And, the solar pump has recirculated 550,000 gallons of water without any mechanical issues, thus providing a sustainable, low-energy remedy when compared to traditional pump and treat systems.

Design to Benefit Society & Environment

Another aspect of remedial design optimization is re-evaluating the way long-term operations and maintenance costs are calculated. The life-cycle analysis can be expanded to look not just at solving the problem but at creating a better future. For example, it can be used to increase flow of ecosystem services to humans. These may include benefits like pollination, groundwater recharge, clean water, carbon sequestration, recreation opportunities, flood protection and wildlife habitat.

Remediation projects also can create direct economic and social sustainability benefits. Reducing a project’s environmental burden almost always helps to reduce costs. Furthermore, increasing land usability can enhance a remediation project’s economic value by creating tax revenue or simply by lifting land-use restrictions required by the previously contaminated property.

In the heart of Milwaukee, Wis., 140 acres of land had been blighted by heavy metals, petroleum, chlorinated organics and asbestos – the residue of more than 125 years of locomotive maintenance. Reincarnation of this land along the Menomonee River began in 2003 when the City of Milwaukee received the property via condemnation. For this brownfield site in the middle of an economically disadvantaged area, remediation was only the first step.

The Redevelopment Authority of the City of Milwaukee (RACM), area businesses and non-profit partners imagined an integrated development rich in recreational, economic and natural assets: the Menomonee Valley Industrial Center (MVIC). The ambitious remediation and development plan included consideration of ecosystem services together with economic development. New “green” and recreational spaces were included in MVIC’s design for the community, such as bike and walking trails, soccer fields, tennis courts, pedestrian bridges, fishing areas and access to the cleaner river at new canoe ramps.

The ecosystem services valuation conducted on the draft brownfield site re-development plan drove the inclusion of riparian and fisheries habitat restoration and fishing access into the site plans. The valuation was also used to identify development alternatives providing the greatest net benefit to the public.

|Ground-level view of stormwater management area with walking bridge at MVIC.

The work resulted in expansion of the types and amount of ecosystem service benefits to Milwaukee citizens. It also documented creation of more than $100 million in ecological, recreational and aesthetic value, helping to attract investment.

Instead of conducting an extensive removal-and-landfilling remediation, the approach isolated contaminated materials while still meeting public safety requirements. A centralized, state-of-the-art stormwater management system was conceptualized in a national design competition. The system was incorporated with green space for overall development, and it not only saved room for future developers but increased the water quality of stormwater discharging to the nearby Menomonee River. The stormwater facility was built using a series of topographic changes, natural plantings, restored wetlands and revitalized riverbanks. This resulted in a 70-acre industrial park with no storm sewers; yet, the system exceeds stringent discharge requirements and maximizes available development space.

By negotiating a first-of-its-kind onsite management plan with the site’s regulatory agencies, including onsite stabilization and encapsulation of asbestos-containing materials, the project saved more than $25 million. Beneficial integration of materials, such as recycled glass, timbers and brick, were used in the new development and were paramount to project success. More significantly, approximately 900,000 cubic yards of crushed concrete were used in development – from former onsite concrete structures to a nearby highway construction project – providing benefits to both projects.

David Misky, City of Milwaukee MVIC project director, explains that “basically, we turned a blighted area that was desolate for almost 30 years into an economic and environmental benefit. The project’s economic sustainability is two-fold. First, CH2M HILL’s remediation analysis confirmed a long-term forecast of $120 million net benefit to the City of Milwaukee as well as creation of 1,500 new jobs. This has become a reality as new businesses have hired local employees and generated tax-based revenue – something this area has not seen for decades. Second, through the economic forecasts and innovative stormwater management that foster environmental sustainability, the City leveraged the ability to obtain millions in grant funds to support the project and to provide new market tax credits for future light industrial business.”

Scale Sustainability to Meet Project Needs

Not all projects have the resources of an MVIC, the backing of a new pilot project or initiative. However, the technologies proven on these projects can be applied to smaller remediation sites with limited scope and funding. The primary requirement is cultivation of an attitude of opportunity to increase environmental and societal value. A recent example is Union Carbide Corporation’s 10-acre Ward Hollow Wildlife Habitat Project in South Charleston, W.Va. As part of a landfill site closure, the project included construction of a shelter, walking path and sampling platforms, and installation of bird and bat boxes. The project also included a 2.5-acre conversion of cover vegetation from tall fescue to a mix of grasses, forbs and flowers, thus creating a prairie-like setting. While these types of projects require investment, the net cost can be lower and return-on-investment significant when all benefits are considered.

Union Carbide’s results included greater use by wildlife and addition of an education program for local students. A natural resource economic project analysis estimated increased ecological service value could be as great as 75 percent (the equivalent of creating an additional 1.9 acres of original habitat) with net present value of educational activities as high as $80,000. The project also attained certification as a Wildlife at Work habitat from the Wildlife Habitat Council, a non-profit organization dedicated to restoration and enhancement of wildlife habitat.

Jerome Cibrik, Union Carbide Corporation remediation leader, reflects, “The project has been great for the company. We have met our commitments and improved the environment at the same time. Our staff is energized about the habitat, and it has enabled us to interact with the community in a very positive way.”

Apply a Fresh Perspective to Maximize Sustainability

An unknown author once said, “People who look through keyholes are apt to get the idea that most things are keyhole shaped.” In a sense, this statement can apply to the remediation industry.

“Only looking at costs and compliance stems from a minimal compliance mindset and many times creates a low threshold of expectations for what tomorrow’s site restoration projects should look like,” says John Mogge, CH2M HILL senior vice president of environmental services. “Such a narrow view does not consider environmental impacts or optimized benefits to society and economy.”

A careful look at each remediation component can reveal opportunities to reduce the project footprint, and the marketplace now supports more options for incorporating lower-impact and recycled materials. For example, waste stabilization typically uses portland cement, which has a potentially high global warming footprint in addition to other burdens. Substituting some or all of the cement with another material exhibiting cementous properties and sourced from waste materials, such as slag from steel production and fly ash from power plants, can avoid the portland cement footprint and create demand for alternative materials.

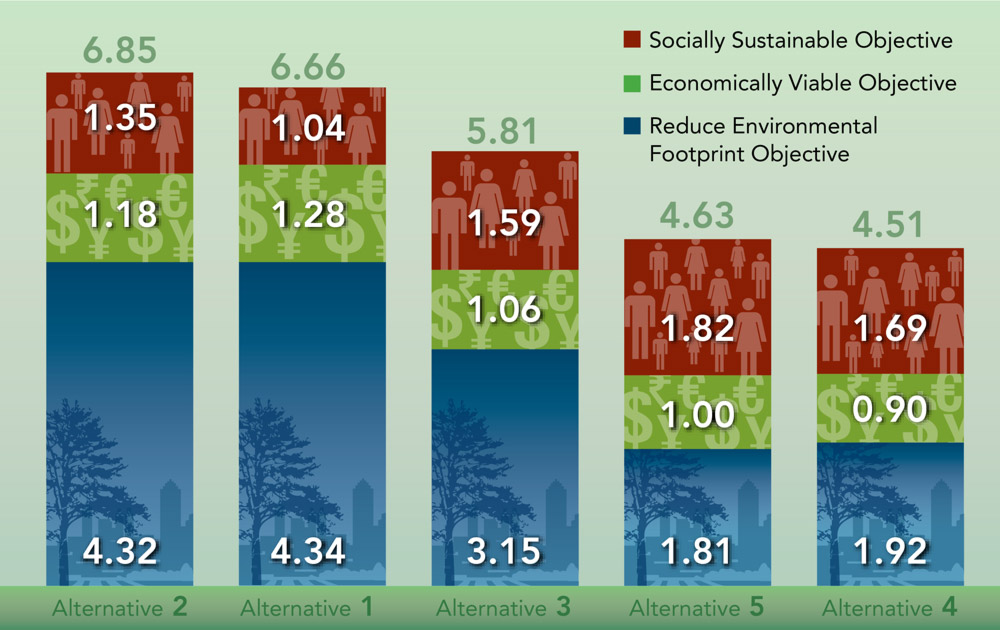

Beyond environmental considerations, when remediation planners are tuned into social factors, they can better design the remediation project to minimize the negative impacts of traffic, noise and odor. Also, by considering local community needs, they can implement better solutions, which maximize future property use and local economic recovery. To help realize this future, CH2M HILL developed a decision-making tool called the “Sustainability Assessment Framework (SAF).” SAF provides a way to help customers make decisions optimizing the three core elements of sustainability.

© CH2M HILL, 2009|The Sustainability Assessment Framework (SAF) enables decision-makers to score remediation alternatives based on a range of objectives and indicators within environmental, social and economic sustainability elements.

A range of objectives and indicators particular to the remediation site and the community’s goals are quantified using common industry tools, such as life-cycle assessment, ecosystems services analysis, economic models, engineering models and public surveys. This information is incorporated into SAF, allowing decision-makers to see which remediation alternative scores highest in terms of environmental, social and economic burdens and opportunities. This information could be used to select an alternative or to come up with creative new combinations that might enhance sustainability of the options they are considering.

By considering sustainability – finding those strings connecting community to environment and economy to ecosystems – remediation projects can do more than clean-up a legacy that limits land use. From MVIC’s new jobs and recreation opportunities to using sunlight to clean groundwater at Travis AFB to creating wildlife habitat on an old landfill, the possibilities to leverage project opportunities can leave a new legacy that expands land use and health for this generation and the next.