Game Changers: Green Engineering & Technology, Part 1

Green engineering and technology are innovative, problem-solving concepts that provide for continuously evolving development and commercialization of products and processes, which “reduce the risk to human health and the environment,” according to the National Academy of Sciences. Similarly, the National Science Foundation maintains these type processes “support human well-being and are compatible with sustaining natural (environmental) systems.” Therefore, as one of the nation’s foremost problem-solvers, it’s no wonder the Naval Research Laboratory (NRL) is on the forefront of developing green game changers.

“One I would call a true ‘game changer’ is our ‘synthetic fuel production at sea’ program. Our work will eventually lead to production of fuel at sea without any dependence on fossil fuel availability or major cost fluctuations,” comments Bhakta Rath, Ph.D. and NRL Associate Director of Research and Head, Materials Science and Component Technology Directorate. “NRL is very much involved in the area we call ‘power and energy,’ focused on force mobility because that’s our business. We work for the Department of Navy (which includes Navy and Marines) and Department of Defense (DoD).”

“All predictors indicate that by 2025 to 2030 the global oil supply will reach a peak after which fuel production and availability will diminish as a function of time. About 58 percent of the Navy’s energy needs are derived from fossil fuel, primarily in the form of aviation fuel and diesel. For our surface combatants, we use F68 diesel and JP5, the latter being a unique high flashpoint fuel in contrast to fuel for Air Force, Army and national use for commercial aviation needs. As we march into the future, can we make the Navy totally independent from unpredictable price fluctuations and availability, and produce our oil as we need it and where we need it?” asks Rath.

Sea Water to Fuel: The Process

Rath maintains that while the Navy and DoD “acquire fossil fuel at around $2.50 to $3 per gallon, at the usage point in Afghanistan, for instance, the price is about $400 per gallon because of fuel delivery logistics from the source to the battlefield. Fuel delivery at sea to our fleet costs in the range of $40 to $60 per gallon because of transportation. The carrier leaves port with about 5 million gallons of fuel for aviation requirements. That fuel runs out between 8 to 10 days. Tankers have to be deployed for both fleet diesel and aviation fuel replenishment, which raises fuel availability cost while the fleet is at sea.”

Rath maintains that while the Navy and DoD “acquire fossil fuel at around $2.50 to $3 per gallon, at the usage point in Afghanistan, for instance, the price is about $400 per gallon because of fuel delivery logistics from the source to the battlefield. Fuel delivery at sea to our fleet costs in the range of $40 to $60 per gallon because of transportation. The carrier leaves port with about 5 million gallons of fuel for aviation requirements. That fuel runs out between 8 to 10 days. Tankers have to be deployed for both fleet diesel and aviation fuel replenishment, which raises fuel availability cost while the fleet is at sea.”

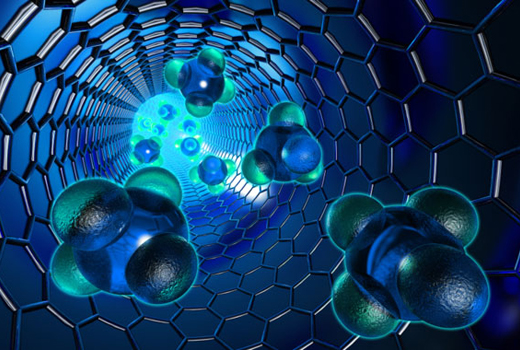

He continues: “Our process will extract hydrogen – carbon dioxide or carbon monoxide – from sea water and convert it via a well-known process called ‘Fischer Tropsch’ to either diesel or aviation fuel. In order to do that, we require some basic research to develop new catalysts for direct use of CO2 and to extract required amounts of carbon from carbonates/bicarbonates. Additionally, we have no problem in scaling-up production of hydrogen from water because there are a number of methods, including simple electrolysis, to extract hydrogen from water.

“NRL has developed a patented process in which we’ll extract carbon dioxide in adequate quantities from sea water. Sea water has about 2 percent dissolved carbon dioxide; the rest is present in the form of carbonates and bicarbonates. Our patented process has demonstrated that we can disassociate carbonates and bicarbonates to produce carbon dioxide. We are working on testing this process in our Key West laboratory and on its potential to scale-up.”

Sea Water to Fuel: Ocean Power Platforms

An important second part of the sea water to fuel conversion is power. Rath explains that the power needs are significant – on the order of 240 megawatts. He comments: “The power resource can be derived from one of the Navy’s nuclear power plants for the future, or we can extract it using ocean thermal energy conversion. If you look at the waters in the tropical or equatorial regions, the surface water is roughly 80 degrees F., whereas the bottom water is cold – less than 40 degrees F. There are various organics, including ammonia, that will freeze at 40 degrees F. and boil at 80 degrees F. that could be used to turn a turbine.

“This means that energy required for this proposed process can be derived from the ocean itself using the temperature differential between surface and bottom water. Of course, in this scenario the platform will be static – located in appropriate ‘sweet spots’ of the ocean where prevailing circumstances are most conducive. But, it will be done at sea to extract power. If, however, we can use nuclear power sources, then a separately designated platform moving with the fleet can produce oil when they need it, where they need it and how much they need it. We’re in the research phase and hope to expand with appropriate funds for scale-up experiments.”

Biomass Considerations

Biomass is another NRL study area. Although many countries and organizations are actively engaged in this process within the wide spectrum of biomass sources, the Navy and DoD are primarily interested in non-food crops, such as camelina and micro-algae. According to Rath, “Micro-algae looks very promising because it claims to produce as much as 10,000 to 12,000 gallons of oil per acre per year from either open or closed water systems. Hundreds of millions of dollars are being spent for oil production from camelina and micro-algaes.

© iStockphoto.com/kkrs

“There are other sources of oil production using food crops – corn, soybeans, safflower, sunflower, rapeseed, oil palm, sugar cane, sorghum. In our view, while in the short term these resources may provide a useful solution, in the long term they will compete with food supply. We don’t think the Navy or DoD can rely upon food crop-derived sources. In particular, ethanol is not usable for either naval or defense purposes.”

Rath goes on to explain that ethanol is a high volatile fuel that decreases the flash point, which is a critical concern for the Navy. A Navy carrier is required to use JP5, which is a higher flash point fuel, because the carrier bottom contains about 5 million gallons of fuel while the carrier top continuously supports jet aircraft taking off and landing. Second, ethanol decreases energy density. The 10 percent added to gas decreases its energy efficiency by roughly 40 percent. In other words, 1.5 gallons of ethanol is the equivalent energy of one gallon of petroleum. Third, ethanol is hydroscopic, which means it absorbs water in due course. Therefore, it will absorb moisture during the storage process. Additionally, it creates a potentially dangerous environment for aircraft flying at very high altitudes.

Rath maintains that the “same story goes for bio-derived diesel. The plans are to use bio-derived fuel additives to fossil fuel diesel. There, the energy density again reduces to about 82-83 percent. The point is that any biomass derived fuel, whether it’s diesel or ethanol, is not going to adequately solve national security needs. The issue is that we need to look at other alternatives.”

High-Energy, Low CO2 Opportunities

“NRL has initiated a research effort, in cooperation with some universities, looking at additives that will provide much higher energy than petroleum fuels. Many solid materials, like aluminum, boron and various carbon derivatives, have much higher energy density than fossil fuel. If we can design various nanotechnology-related processes, producing nanoparticles and adding a catalyst that would ignite the particles simultaneously in the combustion chamber, coat it with a surfactant that will maintain its suspension in the fuel and protect it from oxidation for longer-time storage, this approach will provide much higher energy than fossil fuels. This would enhance, not diminish, fuel energy density. This work is in very preliminary stages, so I would not claim that we have made significant progress at this time,” comments Rath.

Regarding ways to derive energy from non-renewable sources, such as coal to liquid or coal to gas, Rath maintains this to be ineffective for defense purposes “unless we have technology that will provide appropriate carbon dioxide sequestration.” However, the Navy does have commitments to test its engines with fuel additives derived from camelina and micro-algae. In fact, these tests are currently ongoing. NRL is conducting a paper study now to evaluate scale-up viability with respect to cost. The question is whether these fuels will be cost-competitive with projected future fuel price.

Miniature Fuel Cells

© iStockphoto.com/danku

“NRL is working in many other energy areas apart from liquid hydrocarbons or fossil fuels. A major effort in fuel cells is underway with emphasis on miniaturizing them to produce power for unmanned aerial vehicles (UAVs) and unmanned undersea vehicles (UUVs). We are diminishing UAV sizes to smaller and smaller dimensions in order to be more manageable, to be deployed easier and so forth,” comments Rath. Major considerations include power systems, power delivery and power production for both propulsion and power to electronics.

“We have successfully demonstrated a 5-pound payload fuel cell that will produce enough energy to sustain a UAV to a record endurance of about 36 hours. And we are working on increasing that to 50 hours. This approach will provide tremendous advantage to our UAVs while making them smaller and lighter weight. It will also provide the needed power for various communication and transmission. These advances are applicable for both unmanned aerial systems and unmanned submersible systems. For the latter we are working on a larger system for operational life,” explains Rath.

Methane Hydrate

According to the National Academy of Sciences, “Methane hydrate has become the focus of international attention because of the vast potential for human use worldwide. If methane can be produced from hydrate, a reasonable assumption given that there are no obvious technical or engineering roadblocks to commercial production, the nation’s natural gas energy supply could be extended for many years to come. However, some technical and engineering challenges would have to be solved.”

© iStockphoto.com/antonioscarpi

Given that one of NRL’s missions is to understand the ocean, methane hydrate in another research area. Rath comments: “Our early work showed anomalous acoustic deflections from ocean sediment leading to the conclusion that these are deposits of methane hydrate, also called ‘methane clathrate.’ These are compounds of methane and water. More than 50 percent of carbon is deposited on the earth’s crust in the form of methane hydrates. Only one-quarter is stored as oil, coal and natural gas. The remaining 25 percent is distributed as carbon in very low concentrations.

“It is estimated that more than 3 x 1017 cubic feet of methane are deposited along the coastal regions of the U.S. Large deposits are also identified along the continental margins of the entire world, unlike oil reserves, which are located in troublesome regions. If we develop extraction technology we’ll have natural gas for a long, long time to come. NRL is one of the premiere groups studying methane hydrate deposits along the continental margins of the United States. We collaborate with the U.S. Geological Survey (USGS), the National Science Foundation (NSF) and the Department of Energy (DOE) for this effort.”

NRL is still in the exploration stage with its methane hydrate project. The research is very expensive because apart from the research component, it requires ocean work. For example, an expedition for a single experiment at sea would require a minimum 10-day excursion at a cost of $300,000. Rath explains that “because of high cost, NRL has developed a cooperative research program in collaboration with various countries, such as Chile, New Zealand, the United Kingdom, Norway and Japan, as well as with various U.S. agencies. Additionally, permafrost regions of Alaska and Canada have tremendous deposits of methane hydrate on land.”

Power Electronics, Photovoltaics & Inertial Fusion

NRL scientists are also working in the area of power electronics. According to Rath, electrical systems, such as motors, generators, transformers, inductors and capacitors, haven’t changed much since the 1940s. They’re bulky, large and very energy consuming. NRL is working on “novel technologies using semiconductor and superconductor devices and systems to reduce the size and to increase the efficiency of various electrical systems.”

© iStockphoto.com/iLexx

Rath says that NRL scientists are also working on photovoltaics. He comments: “Most of the devices are silicone-based with low energy efficiency. Using semi-conductor technology, we are pushing the frontier to 60 percent efficiency. This, of course, will be cost-intensive and the only potential application will be for space power generation. So, it will be a lot smaller, easily deployable and lighter weight to operate in space.

“Another area we’re working on is the development of a photovoltaic paint. On the battlefield, the soldier can, effectively, take a spray can from his/her hip pocket or backpack, spray it on a rock or ground and, using electrodes, recharge batteries.”

This will be a big relief for the soldier who goes to the battlefield with an 80-pound backpack, of which 22 pounds are in batteries. In addition, when the batteries die, he/she currently removes and tosses them on the ground. This not only creates a larger environmental footprint, but it significantly increases costs. With NRL’s paint, the soldier will not only be able to travel with fewer batteries, decreasing his heavy duty payload without penalty, but will also be able to bring them back to camp since they’ll be rechargeable. NRL is in the stage of developing the paint on a small laboratory scale.

“Last, but not least, NRL has been engaged for the past 25 years in ‘inertial fusion’ – the energy source that gave us the hydrogen bomb. We have not yet been successful in utilizing this energy to produce power. Fusion-based energy will eliminate many problems associated with our current nuclear power plants. NRL has unique capabilities to develop laser-confined inertial fusion for power generation. This work is making steady progress each year,” says Rath.

Central Idea Generation

“The Naval Research Laboratory is the Department of the Navy’s corporate laboratory and is under the command of the Chief of Naval Research. NRL is the principle in-house component in the Navy’s effort to meet its science and technology responsibilities. It boasts a proud history of innovation, which includes radar, GPS, synthetic lubricants, structural materials failure technology, project Vanguard, the excimer laser and advanced sensors for chemical/biological/explosive agent detection.

“NRL scientists are some of the best in the world and include two Nobel laureates and National Medal of Science and National Medal of Engineering recipients. The lab has a long and fruitful relationship with industry as collaborator and contractor and has developed several cooperative research and development agreements (CRADAs). Through NRL, the Navy has direct ties with sources of fundamental ideas in industry, as well as within the academic community, throughout the world, which provides an effective coupling point to the research and development chain for the Chief of Naval Research,” concludes Rath.

© iStockphoto.com/Spectral-Design